Engineering R&D Services

At Cadmaxx, we are committed to assist our clients innovate, optimize costs, and enhance operational efficiency through state-of-the-art technology and domain expertise.

Product Engineering

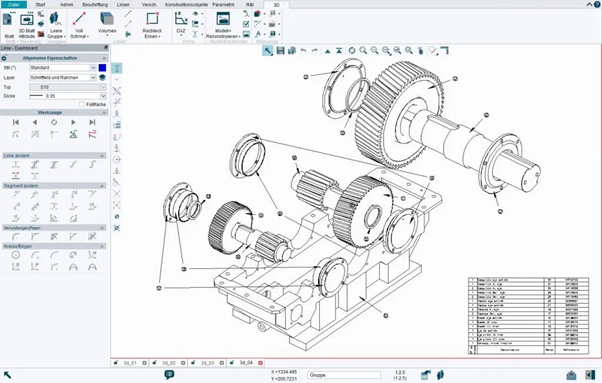

• Computer-Aided Design (CAD)

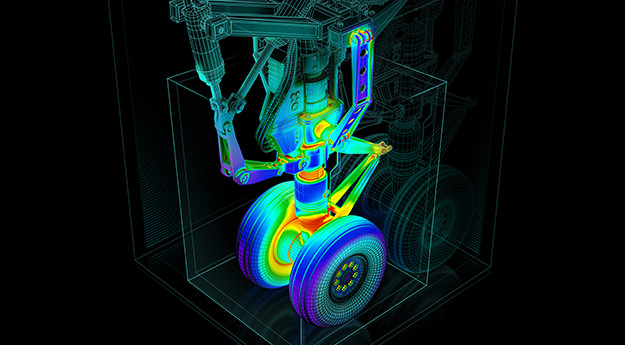

• Computer-Aided Engineering (CAE)

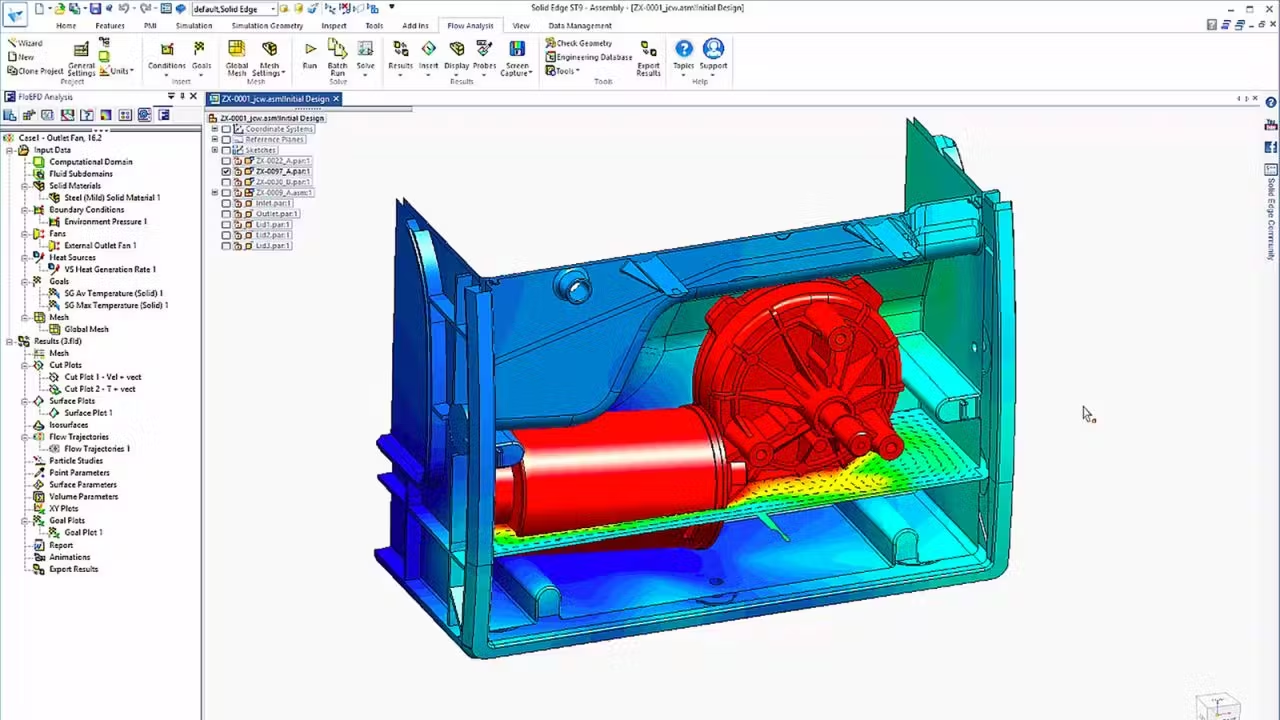

• Computer Aided Manufacturing (CAM)

• Product Design & Development

• Reverse Engineering

• Rapid Prototyping

• 3D Modeling & Simulation

Product Engineering

• Computer-Aided Design (CAD)

• Computer-Aided Engineering (CAE)

• Computer Aided Manufacturing (CAM)

• Product Design & Development

• Reverse Engineering

• Rapid Prototyping

• 3D Modeling & Simulation

R & D Services

• Innovation and Research: We assists organizations in building innovative solutions by focusing on emerging technologies.

• Product Lifecycle Management (PLM): We manage the entire lifecycle of a product, from conceptualization through design, development, testing, and eventual release.

R&D Services

• Innovation and Research: We assists organizations in building innovative solutions by focusing on emerging technologies.

• Product Lifecycle Management (PLM): We manage the entire lifecycle of a product, from conceptualization through design, development, testing, and eventual release.

Skills Offered in Engineering & R&D Services Software expertise

CAD (Computer-Aided Design) Software

• AutoCAD (Mechanical CAD, Electrical CAD, Civil CAD, MEP)

• Autodesk Inventor

• Solid Works

• Solid Edge

• CATIA

• Siemens NX (Unigraphics – Design, Simulation, Manufacturing)

• PTC Creo Elements/Pro (Pro/ENGINEER, Wildfire, Windchill)

• Revit

• ArchiCAD

• PDS (Plant Design System)

• PDMS (Plant Design Management System)

• FIDES

CAE (Computer-Aided Engineering) & FEA (Finite Element Analysis)

• ANSYS

• Abaqus

• MSC Nastran

• MSC Patran

• LS-DYNA

• Pam-Crash

CAM (Computer-Aided Manufacturing) & CNC Programming

• Cimatron

• NC-CAM

• SmartCAM

• Mastercam

• Delcam

• GibbsCAM

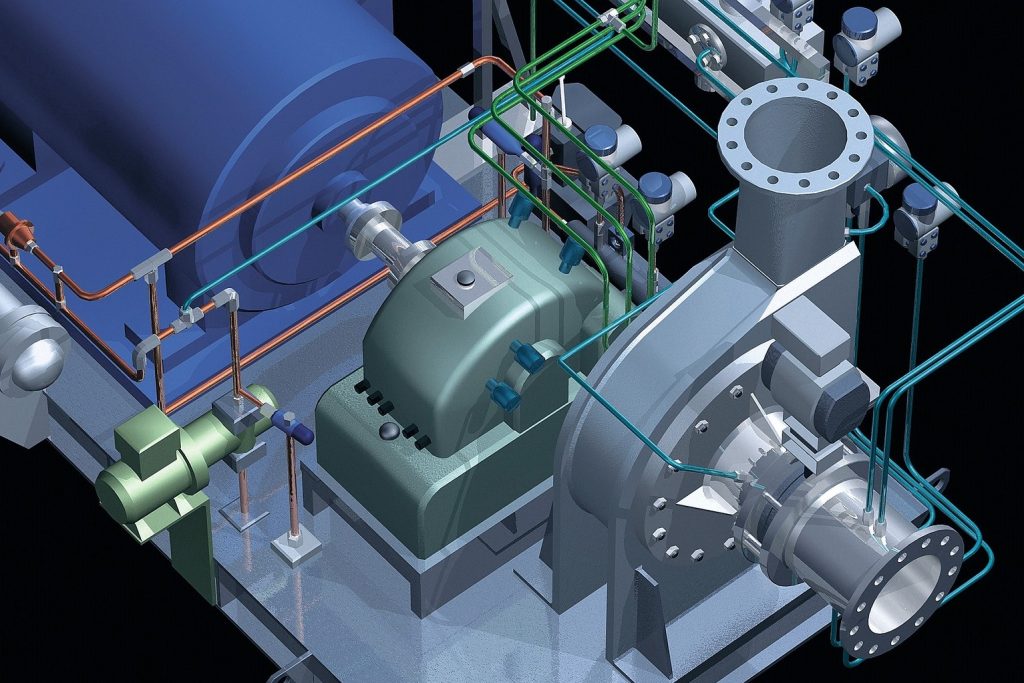

CFD (Computational Fluid Dynamics)

• ANSYS Fluent

• STAR-CD

• Pre-Processing & Meshing Tools

• Hyper Mesh

• ANSA

We offer specialized design and drafting services powered by a team of highly skilled professionals proficient in leading industry-standard CAD and engineering platforms.

Mechanical & Product Design

• AutoCAD – Mechanical

• Autodesk Inventor

• SolidWorks

• Solid Edge

• CATIA

• Siemens NX (Unigraphics – Design, Simulation, Manufacturing)

• PTC Creo (Pro/ENGINEER, Wildfire, Windchill)

Electrical, Civil & MEP Drafting

• AutoCAD – Electrical, Civil, MEP

• Revit (Architecture, Structure, MEP)

• ArchiCAD

Plant Design & Engineering

• PDMS (Plant Design Management System)

• PDS (Plant Design System)

• FIDES (Structural Design & Engineering)

With end-to-end capability in 2D drafting, 3D modelling, simulation, and plant design, we support clients across product development, infrastructure, and industrial projects.

We deliver advanced simulation and analysis services through a dedicated team of CAE experts, helping clients validate, optimize, and enhance their designs before physical prototyping. Our engineers are proficient in industry-leading tools for structural, thermal, dynamic, and crash simulations.

Structural & Multiphysics Analysis

• ANSYS – Structural, thermal, fluid dynamics, electromagnetics

• Abaqus – Non-linear analysis, material modelling, multi-step simulations

• MSC Nastran – Linear and nonlinear structural FEA

Pre/Post-Processing & Solver Integration

• MSC Patran – Pre/post-processing for FEA modelling

• LS-DYNA – Crashworthiness, impact simulation, and high-speed dynamics

• Pam-Crash – Automotive crash and occupant safety simulations

Applications we serve:

• Product durability and life prediction

• Drop test and impact analysis

• Crash simulation and energy absorption

• Vibration and thermal stress analysis

• Safety compliance verification

Our CAE services help reduce design cycles, improve product safety, and ensure regulatory compliance across automotive, aerospace, industrial machinery, and heavy engineering sectors.

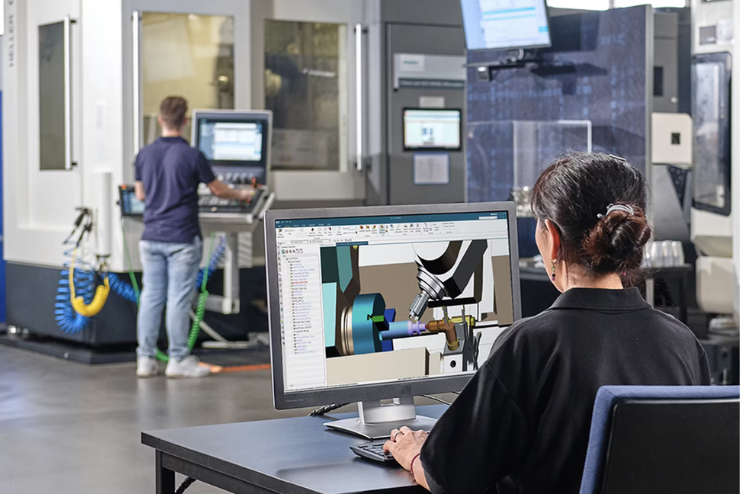

We offer expert-level CAM (Computer-Aided Manufacturing) and CNC programming solutions to streamline manufacturing workflows, reduce lead times, and ensure precision in complex machining operations. Our team is skilled in leveraging advanced CAM software to drive productivity across tooling, Mold making, and component manufacturing.

• CNC toolpath creation for turning, milling, and EDM

• Post-processor development and G-code generation

• Optimization for cycle time, tool wear, and surface quality

• 3-axis, 4-axis, and 5-axis machining support

• Simulation and collision detection

• Manufacturing feasibility studies and process planning

We support industries like aerospace, automotive, heavy engineering, and precision tooling with tailored CAM solutions that ensure high-quality output, optimized machining strategies, and minimized rework.

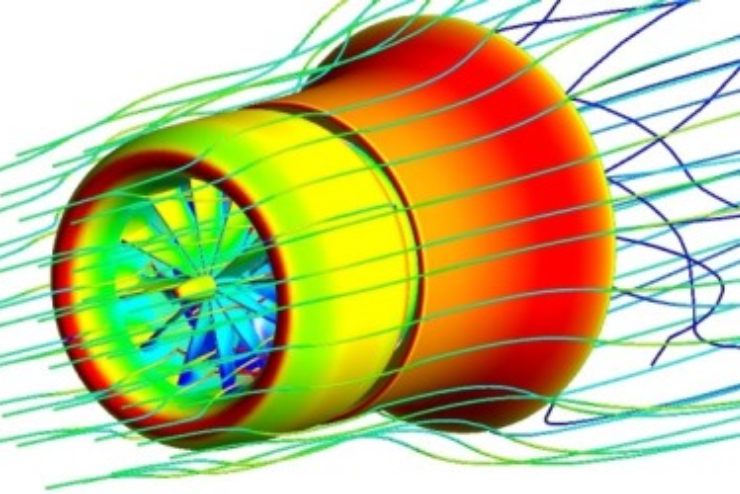

We offer specialized CFD simulation and consulting services, empowering clients to optimize fluid flow, heat transfer, and aerodynamics in complex systems. Our team is equipped with industry-standard software tools and deep domain expertise.

Core CFD Tools

• ANSYS Fluent – High-performance solver for fluid dynamics, heat transfer, turbulence modelling, and multiphase flows.

• STAR-CD – Advanced simulations for engine combustion, emissions, and underhold thermal management.

Pre-Processing & Meshing

• Hyper Mesh – High-quality meshing for complex geometries.

• ANSA – Integrated pre-processing for CFD model setup and mesh generation.

• Other Tools – Geometry cleanup, surface wrapping, and mesh quality optimization.

Applications We Support:

• HVAC & thermal system simulations

• External & internal aerodynamics

• Multiphase flow analysis

• Combustion modelling

• Electronic cooling

• Process equipment optimization.

Our CFD solutions help industries reduce prototyping costs, improve performance, and accelerate product development through physics-driven insights.

We offer end-to-end support and services across a broad spectrum of SAP modules, empowering businesses to optimize operations, streamline processes, and drive digital transformation. Our experienced team delivers SAP-based solutions tailored to your organizational goals.

– SAP FICO

– Financial Accounting & Controlling

– SAP Basis and Security

– System Administration & Security Management

– SAP EWM

– Extended Warehouse Management

– SAP SD

– Sales and Distribution

– SAP CS

– Customer Service

– SAP BI/BW

– Business Intelligence & Data Warehousing

– SAP PS – Project Systems (Logistics Processes)

– SAP ABAP

– Advanced Business Application Programming

– SAP Integration

– CPI

– Cloud Platform Integration

– SAP SF

– Success Factors (HR Cloud Solutions)

– SAP HCM

– Human Capital Management

– SAP CO

– Controlling

– SAP MM

– Materials Management

– SAP PP

– Production Planning

Whether it’s implementation, integration, customization, or ongoing support we ensure your SAP landscape is robust, scalable, and aligned with your business needs.

What is PLM?

A product’s success is shaped not only by its design or functionality but also by its production process, sourcing of components, maintenance, and eventual disposal. Collectively, these stages make up the product lifecycle, and effectively managing this lifecycle is crucial to staying competitive in today’s fast-paced market.

Product Lifecycle Management (PLM) software plays a vital role in this process. It enables geographically dispersed, multidisciplinary teams to collaborate seamlessly with partners and customers using accurate, real-time product information to streamline development.

More than just a management tool, PLM is the foundation of a digital thread strategy ensuring that the right information is available to the right people, at the right time, and in the right context. This drives innovation, enhances supply chain agility, and supports business continuity.

With powerful PLM platforms such as PTC Windchill, Siemens Teamcenter, and Dassault ENOVIA, organizations can integrate solutions across CAD, CAE, FEA, and CAM creating a strong foundation for both cost savings and new revenue opportunities.

From concept and design through manufacturing, service, and end-of-life, PLM unites people, processes, systems, and information on a single platform. By reducing errors, improving collaboration, and accelerating time-to-market, PLM enables businesses to operate more efficiently, sustainably, and profitably.

Lifecycle Stages of PLM

PLM includes all stages of product development, including:

• Concept and design: ideation, feasibility studies, and design iterations with a focus on sustainable materials and processes.

• Development: Prototyping, production planning, and execution with minimal waste and efficient resource use.

• Production and launch: Feedback from the pilot is used to adjust the design and other components to produce a market-ready version. The production of the new product is scaled followed by launch and distribution to the market.

• Service and support: After-sales service, maintenance, and customer feedback to improve product longevity and reduce waste.

• End of season: Disposal, recycling, and obsolescence management to ensure environmentally responsible practices.

Prerequisites of PLM

Interconnect & Collaboration PLM unifies product and process information on a single platform, eliminating data silos and ensuring stakeholders have reliable, up-to-date insights. By serving as the single source of truth, PLM streamlines workflows and enables seamless collaboration across engineering, manufacturing, service, and other teams helping them deliver faster, smarter, and with higher quality.

Enabling Collaboration & Transparency

PLM replaces complexity with transparency, enabling seamless collaboration across domains. It ensures full traceability from issues to components, and from functions to hardware and software parts strengthening both efficiency and accountability.

Increased Efficiency

PLM helps every stakeholder quickly find, share, and reuse product data while synchronizing and automating processes. Product launch teams rely on PLM to ensure critical feedback and insights are shared across the entire development cycle. With connected process plans and work instructions, PLM enables a smooth transition from development to manufacturing delivering products with greater speed, agility, and reliability.

Enforced Product Compliance

PLM standardizes processes and automates controls to ensure consistent, high-quality products across all sites. Its data-driven approach guarantees regulatory compliance while minimizing risks of errors and nonconformities.